Framed Cabinets vs Frameless Cabinets

When it comes to selecting the right type of cabinets for your kitchen, bathroom, or any other space in your home, there are many factors to consider. One of the key decisions you will have to make is whether to go for framed or frameless cabinets. While both types of cabinets offer unique benefits, the choice you make will depend on your individual needs and preferences.

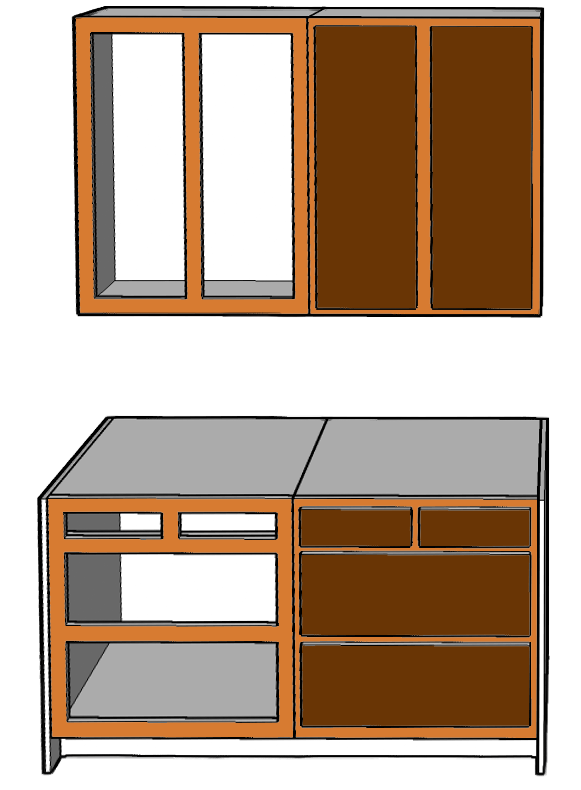

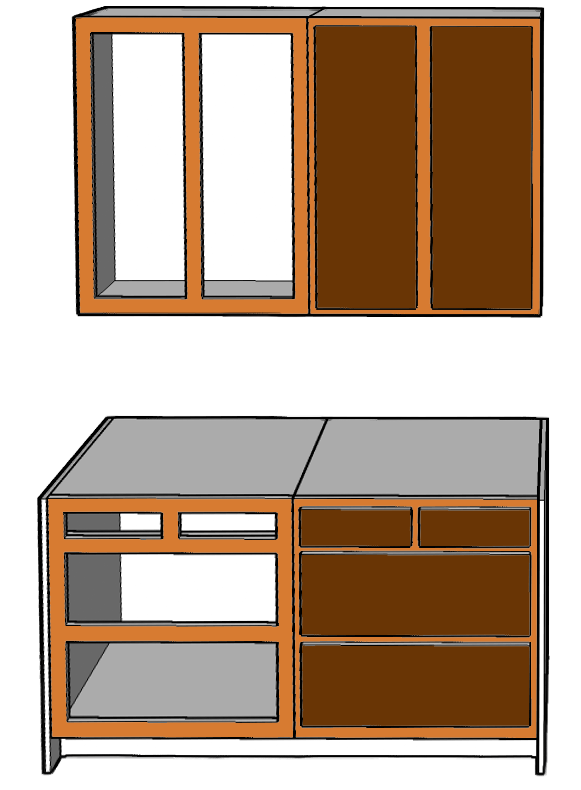

FRAMED CABINETS

Popular in the American Market

Framed cabinets have an extra overlaying structure or frame on the front of the cabinet box (light brown in the picture).

The door (dark brown) is connected to the box using hinges that are installed on the cabinet frame. Older framed cabinets have much larger gaps between doors & drawer fronts where the face frame on the cabinet box is visible.

In the US cabinet market, framed (aka face frame) cabinet construction is the most popular method and uses a solid hardwood constructed frame on the front/face of a cabinet. The cabinet overlay creates a sturdy structure and can be paid with a variety of door styles.

Face frame cabinets are generally made with solid hardwood face frames and plywood for the remaining cabinet components.

These cabinets can either be naturally finished to showcase the beauty of the wood or painted/stained to any number of decorative colors to match the style of your home.

Note: It’s possible to replace doors on a face framed system, however it is not possible to close the larger gaps where the face frame on the box is visible.

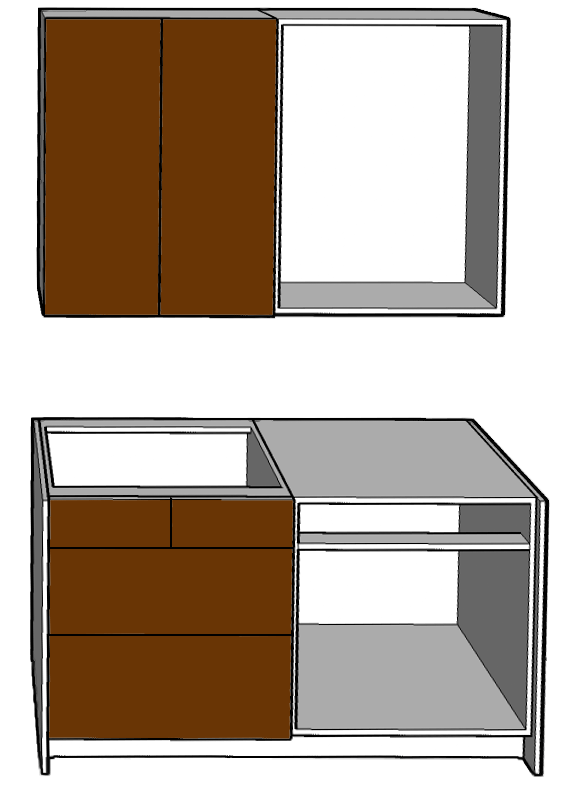

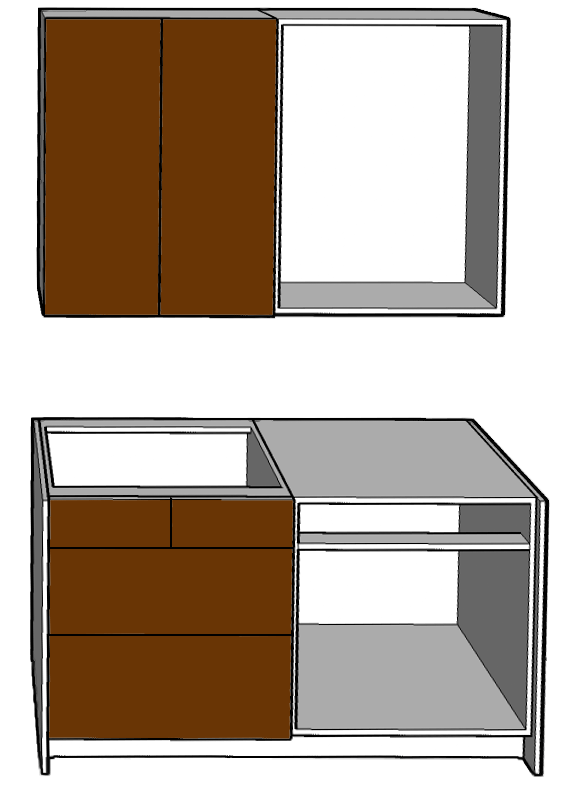

FRAMELESS CABINETS

Popular in the European Market

Frameless cabinets do not have an additional face frame.

The door (dark brown) is connected directly to the box cabinet with hinges installed on the box. They are also known as full access cabinets, with no divider between pairs of doors or drawers when open.

Even though face frame cabinetry is the most common in the US, there is a large part of the market that builds frameless cabinets. What sets these apart from frame cabinets is there is no face frame on the front of the cabinet. This creates a sleek look when opening the doors and drawers.

Frameless cabinet options are generally constructed using melamine board with edge banding or veneered/laminated plywood.

These cabinets are typically painted or stained to match the style of your home.

CHOOSING THE RIGHT FRAMED OR FRAMELESS CABINETS

It can be difficult to decide whether to choose framed vs frameless kitchen cabinets in your home. There are some advantages and disadvantages to each style of cabinets.

Pros of Framed Kitchen Cabinets

There are several benefits of using framed cabinetry in your storage or kitchen design:

- Sturdiness: The frame around the perimeter of the cabinet provides added stability and support, making framed cabinets a good choice for heavy use areas like the kitchen. Framed cabinets have an additional layer of hardwood that also helps to increase the sturdiness of the cabinetry. The cabinets are built to last.

- Adjustability: The frame around the cabinet provides space for adjusting the shelves or drawers, making it easier to create a custom interior for the cabinet.

- Affordable: Framed cabinets are typically slightly less expensive than frameless cabinets, making them a good option for those on a tight budget when redesigning their home or kitchen.

Pros of Frameless Cabinets

There are several pros of using frameless cabinet designs:

- Increased interior space: The lack of a frame around the cabinet box means more usable interior space, making frameless cabinets a good choice for those who need extra storage or kitchen space.

- Sleek, modern appearance: The lack of a frame around the cabinet box gives frameless cabinets a sleek, flush, and modern appearance that is ideal for contemporary kitchen designs.

- Easy to clean: The lack of a frame around the cabinet box makes frameless cabinets easier to clean and maintain.

KEY DIFFERENCES BETWEEN FRAMED AND FRAMELESS CABINETS

While both framed and frameless cabinets offer their own unique benefits, there are several key differences between the two that you should consider when you shop for cabinets and before making a decision. Find your favorite cabinet and get started on your kitchen construction project.

Space

One of the biggest differences between framed and frameless cabinets is the amount of storage space that is available. Because frameless cabinets do not have a frame, they offer more storage space as the cabinet box can be used more efficiently. This is a great option if you want to free up space in your kitchen for cooking. On the other hand, framed cabinets can have limited storage space as the frame takes up some of the space inside the cabinet.

Style

The style of framed and frameless cabinets is another key difference between the two options. Framed cabinets have a more traditional look and feel, making them a popular choice for a classic kitchen or traditional design style. On the other hand, frameless cabinets have a modern and contemporary look that is perfect for a kitchen with a more contemporary design style.

Accessability

Another difference between framed and frameless cabinets is accessibility. Frameless cabinets offer better accessibility. With open cabinet fronts, it is easier to access items inside the cabinets because there are no frames getting in the way. This makes it easier to reach items that are stored in the back of the cabinet, which can be a real convenience when you're in a hurry. On the other hand, framed options have the face overlay which can make it difficult to access items inside the cabinets.

Installation

Framed cabinets have a solid frame around the perimeter of each cabinet box, which provides structural support and stability. Installing framed cabinets is a bit more complex than installing frameless cabinets, as the frames need to be properly aligned and secured to the back of the wall.

On the other hand, frameless cabinets have no frame and instead rely on the strength and stability of the cabinet box itself. The lack of a frame allows for more flexibility in the design and placement of shelves and drawers. Installation of frameless cabinets is a bit more straightforward but they also need to be securely attached to the back or sides of the wall.

When it comes to installation, both framed and frameless cabinets require a sturdy and level base for proper installation. For framed cabinets, the frames need to be properly aligned and secured to the wall, and for frameless cabinets, the cabinet boxes must be firmly attached to the sides of each other and to the wall.

GETTING STARTED WITH YOUR FRAMED OR FRAMELESS KITCHEN CABINET PROJECT

We recommend either hiring or at least consulting with a construction professional who will guide you in your cabinet installation project. Cabinets, whether framed or frameless, aren't overly challenging to install but mistakes in the process can lead to their shortened lifespan or even break the cabinets.

Here's what you need to get started with installing your new cabinets:

Measure your kitchen and make a construction plan.

Before you start shopping for cabinets, it's important to measure the space where they will be installed. This will help you determine the number of custom cabinets you need and the best layout for your kitchen.

Choose your cabinets.

With your kitchen measurements in hand, it's time to choose the cabinets that will work best for your space. Consider the style, color, and material that will complement the overall look of your kitchen. Knowing what you want will help you decide whether to go with wood frame or frameless options.

Gather the necessary tools.

Installing cabinets requires a variety of construction tools, including a drill, saw, level, and screwdriver. Make sure you have all the tools you need before you begin the installation process.

Prepare the space.

Remove any existing cabinets, countertops, and appliances to clear the way for your new cabinets. This will also give you the opportunity to repair any damage to the walls or flooring before you start the cabinet construction and installation process.

Read the instructions.

Before you begin installing your cabinets, make sure you have a clear understanding of our construction process and don't hesitate to contact us if something is unclear. Pay close attention to any cabinet safety warnings and guidelines.

GETTING A QUOTE FOR FRAMED OR FRAMELESS KITCHEN CABINETS

If you would like a quote for new doors and drawer fronts, please email us a list of the following:

For doors - we need width x height and quantity of each;

For hinge boring size & location info, we need:

- Distance between the edge of the door and the edge of the hinge cup (ours are normally 5mm, other manufacturers vary and may not be interchangeable with ours)

- Diameter of the hinge cup (ours are normally 35mm, other manufacturers vary and may not be interchangeable with ours)

- Distance from the top and bottom edge of the door to the centerlines of the top & bottom hinge cups (ours are normally 3", other manufacturers vary and may not be interchangeable with ours)

- For doors with more than 2 bores we need the distance from the center of the top & bottom bores to the center of the middle bores

For drawer fronts, finished end panels, fillers and toekick pieces - we only need width x height and quantity of each.

Please be sure to include a shipping address and phone number, as well as the finish material you would like for your new cabinets.